Classification of press machines

Classification of press machines

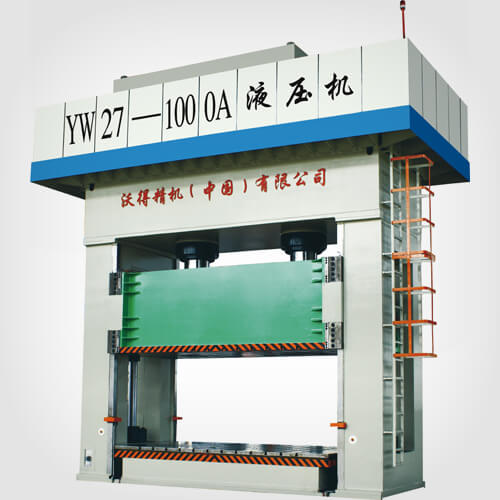

Wode Precision Machinery specializes in providing products such as press machines, always adhering to customer-centered, quality centered, and pre-sales and after-sales service as the focus, always ensuring that customers can rest assured and at ease.

Press, also known as hydraulic press, hydraulic press. The press machine consists of four parts: an upward pressure four column hydraulic press; Combined control cabinet; Electric heating system and insulation device; Mold conveying platform. The above components adopt integrated design, making them elegant and beautiful in appearance, compact in structure, simple and reliable in operation, and convenient in maintenance. Press machines are divided into four categories: screw press, crank press, pneumatic press, and multi-station press.

A forging machine that uses screws and nuts as transmission mechanisms and converts the forward and reverse rotation motion of the flywheel into the reciprocating motion of the slider through screw transmission. During operation, the electric motor accelerates the rotation of the flywheel to store energy, while pushing the slider downward through screws and nuts.

The crank press is the most commonly used cold stamping equipment used as a working platform for cold stamping molds. Its structure is simple and convenient to use. According to the different structural forms of the bed, the crank press can be divided into open crank press or closed crank press; According to the number of driving links, it can be divided into single point press or multi-point press; According to the number of sliders, it can be divided into single action press or double action press.

A pneumatic press is a press composed of a gas-liquid booster cylinder, a workbench, and a control logic valve. Using pneumatic and hydraulic power for output! The 3KG -7KG gas source can reach a high-pressure output of 1 ton to 100 tons.

A multi-station press is an advanced press equipment that integrates multiple presses and is generally composed of a wire head unit, a feeding mechanism, a press, and a wire tail part. The fastest beat can reach over 40 beats per minute, which can meet the requirements of high-speed automated production.

Over the years, Wode Precision Machine has achieved tremendous development in the fields of bending machines, hydraulic presses, CNC shearing machines, and press machines. With the development of the industry and the upgrading of competition, it has improved the technical content of its products, possesses independent patents and designs, and focuses on brand building and marketing. In the machine tool industry, there is a good reputation, and more and more manufacturers are willing to choose Wode Precision Machine.