JX36 series closed double point press

JX36 series closed double point press

Product Overview

Derived from professionalism to achieve the best

The JX36 machine tool is suitable for various needs in the diversified metal forming industry, such as continuous stamping dies and fully automatic mobile stamping dies, which can be fully customized according to customer needs.

The convenience of JX36 machine tool operation can meet various operating modes and meet the various needs of the manufacturing industry in today's world.

The JX36 series products introduce advanced technology from the world, with high resistance to eccentric loading, long service life, and greater improvement in enterprise efficiency, while ensuring product quality and meeting user needs.

Performance characteristics

·Steel plate welded structure, upper crossbeam, column, and base are pre tightened with tensioning bolts to form a closed structure, with high strength and stiffness;

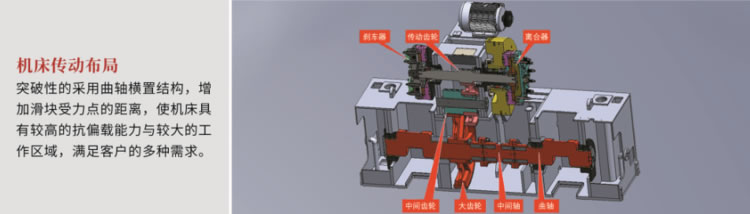

·The breakthrough is the adoption of a transverse crankshaft structure, which increases the distance between the force points of the slider, giving the machine tool a high ability to resist eccentric loads and a larger working area;

·Adopting a split dry block friction clutch and brake, it has the characteristics of low inertia, high torque, and low noise;

·Using PLC to accurately control the two dual valves of the clutch brake, ensuring coordinated action and reliable interlocking of the clutch brake;

·The use of thin oil circulation lubrication greatly improves the working speed of the machine tool;

·The slider adopts a four corner eight sided long guide rail, which has good guidance and high accuracy;

·Electric mold adjustment, accurate reading to 0.1mm;

·Can be equipped with various types of automated peripheral equipment, greatly improving production efficiency;

·High safety, multifunctional electronic control system.

Purchase consultation